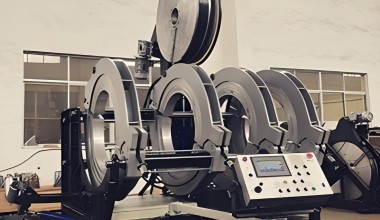

The hydraulically operated butt fusion machine features robust, compact, and rugged reliability.

About RIYANG

SINCE 2010

Welcome To RIYANG

RIYANG Pipe Fusion Machine

Ensuring Safe Connections for Seamless Pipeline Networks

Experience

- 15+

Years of experience and know-how in pipe fusion industry.

Global Employees

- 30+

Highly qualified employees worldwide.

Country

- 65+

Marketplaces witness the stability, satisfactory service and Riyang development.

Market Growth

- 30%

Annual sales growth illustrates the well acceptance of Riyang pipe fusion machines.

Made in China

- 98%

In-house production “Made in China” ensure adequate supply of accessories and butt fusion machines.

Machines in Action

- 3200+

Riyan Fusion welding machines in operation all over the world.

Brand Story

What RIYANG Stands For

RI

- Symbolizes light, warmth, and energy

YANG

- Represents growth, progress, and soaring ambition.

Together, they reflect our commitment to bringing our customers innovative, high-quality fusion welding solutions, helping them succeed and thrive in a rapidly evolving industry.

Radiant and Rising, Welding Endless Possibilities.

Brand Story

RIYANG History

Brand Story

What We Stand for

Our Vision

Riyang is a reliable supplier of thermoplastic welding machines. The Riyang brand represents product reliability, pioneering innovation, accurate communication, and outstanding after-sales service. We are committed to the establishment of a successful community of production, design, service and problem solver, all of which will be closely related to our global customers, partners and employees. We will work on a better global infrastructure.

Our Mission

Riyang makes no compromise concerning reliability. Over the past 15 years, Riyang has been the most reliable brand in the thermoplastic welding technology from China. Continuous pursuit of product reliability is the goal we have been striving for. And we never abandon a customer. The usual rule is: Once an Riyang customer, always an Riyang customer. Our customers worldwide remain loyal to the Riyang brand and recommend us to others.

Our Value

Riyang wants to sharpen the awareness of values and to describe the way how we at Riyang want to deal with colleagues as well as our customers, suppliers and all other business partners.

- Customer orientation

- Hands-on team spirit and mutual respect

- Open and honest communication

- Embrace changes

- Gratitude and positive energy

With great enthusiasm and interest, Jack Chan, the founder of Riyang, has been committed to the business of pipe fusion machines and promoting Riyang brand.

"We don't just follow business models—we focus on improving quality, innovating, and creating solutions that truly meet our customers' needs," he explains. "Great products speak for themselves."

Jack ChanCEO

Jack's mission is simple:

Team

Meet Our Core Team

At Riyang, we are committed to sustainability and corporate social responsibility. We prioritize using eco-friendly materials and continually improve our manufacturing processes to minimize environmental impact. Our innovations enhance fusion welding efficiency and contribute to a greener future for the industry, ensuring our solutions are both efficient and environmentally responsible.

More RIYANG

Stay Updated with Our Latest News

Need Assistance? Contact Us!

We're here to help with tailored solutions for all your plastic welding needs.

- Free Technical Consultation

- Product Guidance

- Fast, Reliable Support

Big Pipes, Big Solutions!

Need reliable pipe fusion equipment for large-diameter pipe projects? Our heavy-duty pipe fusion welding machines are for the job—strong, precise, and ready to perform.

WE ARE WILLING TO TAKE YOUR CHALLENGEBecome Our Distributor!

Join Riyang family as a distributor and support infrastructure development worldwide.

- Exclusive Products

- Training & Support